Ever felt overwhelmed by clutter in a room? We’ve all been there. Creating functional and attractive storage is a game-changer. That’s where custom drawer design comes in – a perfect blend of form and function.

As DIY enthusiasts ourselves, we know the joy of making something with our hands. Our guide on drawers woodworking will teach you to make beautiful and practical storage. Whether you’re experienced or just starting, our step-by-step instructions will help you get professional-looking results.

👉👉 Start your woodworking journey with Ted’s 16,000 plans »

Key Takeaways

- Learn the basics of custom drawer design to enhance your home’s storage.

- Discover step-by-step guides for creating functional and attractive drawers.

- Understand the importance of choosing the right materials for your DIY drawers.

- Get tips on how to add a personal touch to your woodworking projects.

- Explore common mistakes to avoid in drawers woodworking.

The Art and Utility of Drawer Construction

Drawer construction is an art that blends function with beauty. It makes a room look and feel better. When we build drawers, we’re not just making storage. We’re adding to the room’s beauty.

Why Custom Drawers Matter in Home Organization

Custom drawers are key to organizing your home. They fit your storage needs perfectly, keeping everything in its place. “A well-organized home is not just about having enough storage; it’s about creating a space that feels serene and manageable,” says a seasoned woodworker. Custom drawers help you keep your space tidy and stylish.

Balancing Functionality and Aesthetics

Building drawers requires balancing function and beauty. Choose the right materials and design smart drawer systems. Use hardware that matches your decor. This way, we create drawers that are both useful and attractive.

Planning Your Drawer Project

Starting a drawer project needs a good plan. This plan should think about how it looks and works. When you begin your woodworking projects, a clear plan helps you avoid mistakes. It makes sure your DIY drawers look just as you imagined.

Determining Drawer Dimensions and Purpose

First, figure out the size and use of your drawer. Think about what you’ll store in it and where it will go. For example, a kitchen drawer for utensils is different from a bedroom drawer for clothes. Knowing its purpose helps you decide its size and what features it should have.

Selecting a Drawer Style

The drawer’s style should match the room’s furniture and decor. You can pick from modern, traditional, or a mix, based on your taste and the room’s look. The style you choose affects the materials and hardware you’ll need for your drawer assembly.

Creating Detailed Drawer Plans

After deciding on size, purpose, and style, make detailed plans. Draw your design, list the materials, and think about how you’ll join the pieces. A detailed plan makes building easier and less stressful.

👉👉 Start your woodworking journey with Ted’s 16,000 plans »

By following these steps, you’re on your way to making a drawer that’s both useful and looks great. It will fit perfectly in your woodworking project.

Essential Tools for Drawers Woodworking

To start a drawers woodworking project, you need basic tools. These tools make the work easier and faster. Whether it’s a simple drawer or a complex piece, the right tools are key.

Hand Tools for Drawer Construction

Hand tools are the core of woodworking, including drawers. You’ll need chisels for small wood removal, hand saws for cutting, and hand planes for surface smoothing. “A good craftsman is known by his tools,” as the saying goes. The right hand tools greatly improve your work’s quality.

- Chisels

- Hand saws

- Hand planes

- Mallets

Power Tools That Enhance Efficiency

Power tools boost efficiency and precision in drawers woodworking. Table saws are essential for straight cuts, and routers create decorative edges. Drill presses are great for precise drilling, and jigsaws are useful for curved cuts.

| Power Tool | Primary Use |

|---|---|

| Table Saw | Making straight cuts |

| Router | Creating decorative edges |

| Drill Press | Precise drilling |

Measuring and Marking Tools for Precision

Precision is vital in drawers woodworking. Measuring and marking tools are essential for accurate cuts and assemblies. Calipers measure precisely, marking gauges create consistent marks, and squares ensure perfect angles.

👉👉 Start your woodworking journey with Ted’s 16,000 plans »

With these tools and the right woodworking techniques, you’ll create beautiful, functional drawers. They’ll enhance any furniture piece.

Selecting the Right Materials

Choosing the right materials is key for making drawers that work well and look good. When you’re creating a custom drawer design, the materials you pick will affect how well it lasts and looks.

Wood Types Ideal for Drawer Construction

For DIY drawers, you have many wood types to choose from. Oak and maple are favorites because they’re strong and have nice grain patterns. If you want to save money, think about using pine or plywood.

- Oak: Durable and resistant to wear

- Maple: Hardwood with a smooth finish

- Pine: Cost-effective with a rustic appeal

- Plywood: Versatile and budget-friendly

Hardware Options for Drawer Functionality

The hardware you pick can really change how your drawers work. For smooth opening and closing, go for drawer slides made for heavy use. Also, drawer handles or knobs come in many styles to fit your cabinet’s look.

👉👉 Start your woodworking journey with Ted’s 16,000 plans »

Adhesives and Fasteners

When putting together your drawers, picking the right adhesives and fasteners is important. Use strong wood glue to stick wood pieces together. Then, pick nails or screws that fit the thickness of your wood.

By carefully choosing your materials, you can make drawers that are not just useful but also beautiful and durable.

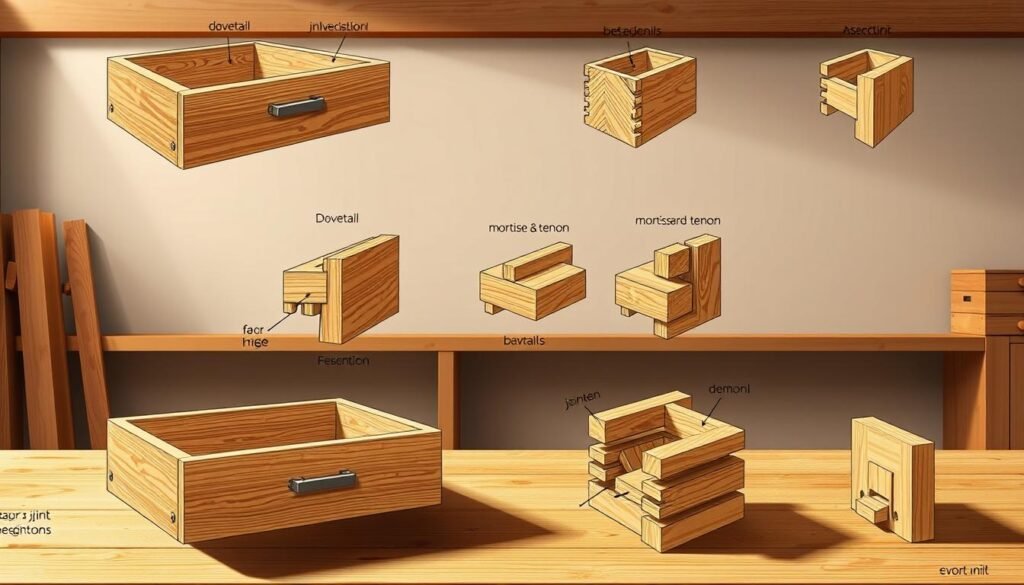

Understanding Drawer Joinery Techniques

To make drawers that last, knowing various joinery techniques is key for woodworkers. Drawer joinery is more than just putting wood together. It’s about making something strong, useful, and beautiful. The joinery method you pick can greatly affect your drawers’ durability and look.

👉👉 Start your woodworking journey with Ted’s 16,000 plans »

Dovetail Joints: The Gold Standard

Dovetail joints are top-notch in drawer making because they’re very strong and hold up well against pull-out forces. These joints are not only strong but also show off your craftsmanship. They might take more skill and time, but they’re worth it.

Box Joints for Strength and Visual Appeal

Box joints, or finger joints, are another great choice for drawers. They’re strong and look good on your drawers’ corners. Box joints are simpler to make than dovetail joints, thanks to tools like table saws or jigs. This makes them a favorite among woodworkers.

Simple Joinery Methods for Beginners

If you’re new to woodworking, start with simpler methods like butt joints or rabbet joints. These are easier to learn and don’t need special tools. They might not be as strong as dovetail or box joints, but they can make great drawers with the right tools and hardware.

Knowing about different joinery techniques lets you pick the best one for your project. It depends on your skill, tools, and what you want to achieve. Whether it’s a simple drawer or a complex piece, the right joinery can make a big difference.

Step-by-Step Drawer Box Construction

Let’s explore how to build a strong drawer box. It’s a key woodworking project that needs focus and the right methods.

Measuring and Cutting with Precision

To begin, measure and cut your drawer box parts carefully. Use a good tape measure and a sharp pencil for marking. Double-check your measurements to avoid mistakes. For straight cuts, use a table saw or circular saw. For angled cuts, a miter saw is best.

👉👉 Start your woodworking journey with Ted’s 16,000 plans »

Creating the Drawer Sides, Front and Back

After cutting, assemble the drawer’s sides, front, and back. Use dovetail or box joints for strong corners. Apply wood glue and clamp the pieces until the glue dries.

Cutting and Fitting the Drawer Bottom

The drawer bottom should fit perfectly. Cut it to size with a table saw or router. It slides into grooves in the sides and front. Make sure the grooves are aligned right to avoid drawer problems.

Assembly Techniques for Square and True Drawers

To make sure your drawer is square, clamp it while the glue dries. Check the diagonals to confirm it’s square. If not, adjust the clamps to fix it before the glue sets.

| Component | Material | Thickness |

|---|---|---|

| Drawer Sides | 3/4″ Plywood | 12″ High |

| Drawer Front/Back | 3/4″ Plywood | 12″ High |

| Drawer Bottom | 1/4″ Plywood | 1/4″ Thick |

By following these steps and using the right materials and techniques, you can make a sturdy drawer box. It’s a rewarding DIY project that adds value to your furniture, whether you’re experienced or just starting.

Drawer Slide Installation Guide

The smooth operation of your drawers depends on the correct installation of drawer slides. As we dive into the world of drawers woodworking, it’s essential to understand that drawer slides are not just a functional component but also impact the overall user experience.

Types of Drawer Slides and Their Applications

Drawer slides come in various types, each designed for specific applications. Soft-close slides are perfect for heavy-duty drawers, providing a silent and smooth closing mechanism. Under-mount slides are ideal for high-end cabinetry, giving a sleek and minimalist look. When choosing drawer slides for your custom drawer design, consider the weight capacity, drawer size, and desired functionality.

👉👉 Start your woodworking journey with Ted’s 16,000 plans »

Measuring and Marking for Slide Installation

Accurate measurement is key for the successful installation of drawer slides. Start by measuring the width and depth of your drawer box. Then, mark the location of the slides on both the drawer and the cabinet. Ensure that your markings are precise and consistent to avoid any issues during assembly. A digital caliper can be a valuable tool in achieving precise measurements.

Mounting Techniques for Smooth Operation

Mounting drawer slides requires attention to detail to ensure smooth operation. Begin by attaching the slides to the drawer box, following the manufacturer’s instructions. Then, mount the slides to the cabinet, making sure they are level and securely fastened. Test the drawer’s movement several times to ensure it glides smoothly and evenly. Adjust as necessary to achieve the desired performance.

By following these guidelines and choosing the right drawer slides for your project, you’ll be able to create drawers that not only function beautifully but also enhance the overall aesthetic of your cabinetry.

Advanced Drawers Woodworking Techniques

In this section, we’ll explore advanced woodworking techniques. These methods can turn your drawers into stunning masterpieces. You’ll learn how to make drawers that are both beautiful and practical.

Creating Curved and Specialty Drawer Fronts

Curved and specialty drawer fronts can make your woodworking projects stand out. You’ll need to learn techniques like steam bending or using a curved jigsaw. Steam bending creates smooth, continuous curves, while a curved jigsaw is great for detailed designs. For example, you can make a modern kitchen drawer with a flowing curve using steam bending.

👉👉 Start your woodworking journey with Ted’s 16,000 plans »

Inlay and Veneer Applications

Inlays and veneers add beauty to your drawers. Inlay work involves inserting wood or materials into grooves, making patterns or designs. Veneer application covers large areas with thin wood slices, giving a luxurious look without the cost of solid hardwood.

| Technique | Description | Skill Level |

|---|---|---|

| Inlay Work | Inserting materials into grooves for decorative patterns | Advanced |

| Veneer Application | Applying thin wood slices for a high-end finish | Intermediate |

| Steam Bending | Bending wood into curved shapes using steam | Advanced |

Custom Drawer Organizers and Dividers

Custom organizers and dividers boost your drawers’ functionality. Designing compartments for specific items increases storage. Dividers made from contrasting wood add beauty. For instance, you can make dividers for utensils in a kitchen drawer or jewelry in a dresser.

Using these advanced techniques in your woodworking projects will enhance both function and beauty. Whether you’re making curved fronts, inlays, or custom organizers, these methods will help you create exceptional pieces.

Troubleshooting Common Drawer Problems

Let’s tackle common problems with drawers and how to fix them. Even with careful planning and building, issues like binding, misalignment, and loose joints can happen. We’ll look at practical solutions to these problems, helping you fix your drawers well.

Fixing Drawers That Bind or Stick

Drawers that bind or stick can be frustrating. This often happens because the drawer slides are not aligned right or there’s too much friction. To fix this, make sure the drawer slides are aligned correctly and clean them out. Using a lubricant, like wax or silicone spray, on the slides can also help.

- Check and adjust the drawer slides for proper alignment.

- Clean out any debris or dust from the slides.

- Apply a lubricant to reduce friction.

Addressing Drawer Front Alignment Issues

A misaligned drawer front can make your furniture look bad. First, check if the drawer box is aligned right in the cabinet. If it’s not, loosen the screws on the drawer front, move it to the right spot, and then tighten the screws. For more precise adjustments, use drawer front alignment clips.

- Check the alignment of the drawer box within the cabinet.

- Loosen the screws on the drawer front.

- Realign the drawer front and secure it with screws.

Repairing Loose Joints and Connections

Loose joints and connections can make your drawers unstable and less functional. To fix this, check the joints and re-glue any loose spots. For extra strength, add screws or dowels to the joints. Regular checks and maintenance can stop these problems before they start.

👉👉 Start your woodworking journey with Ted’s 16,000 plans »

Key steps include inspecting the joints, re-gluing loose areas, and reinforcing with screws or dowels.

Conclusion: Mastering the Art of Drawer Construction

Creating functional and attractive storage solutions is a mix of skill, patience, and creativity. By mastering custom drawer design and diy drawers, you can improve your home organization. You can also add a personal touch to your furniture.

In this guide, we covered the key tools, materials, and techniques for drawer construction. We talked about drawer joinery and installing drawer slides. Each step is important for making drawers that work well and look good.

Keep exploring and trying new designs and techniques as you continue woodworking. Whether you’re experienced or just starting, diy drawers offer endless creative possibilities. So, grab your tools, and let’s get building!

🛠️ Want the Look Without the Sawdust? Here’s Your Shortcut

There’s something rewarding about building a wooden piece with your own hands—but let’s face it, not everyone has the time, tools, or space for a full DIY project.

💡 That’s why I recommend Ted’s Woodworking Plans – a massive library of 16,000+ step-by-step plans for every kind of woodworking project you can imagine. From pet houses to holiday gifts, you’ll get:

✨ Easy-to-follow blueprints

🧰 Complete material & cut lists

🪚 Projects for all skill levels

👉👉 Start your woodworking journey with Ted’s 16,000 plans »

🔍FAQ

What are the most common types of wood used for drawer construction?

How do I determine the right size for my drawers?

What is the best type of drawer slide to use?

How do I assemble a drawer box?

What are some common mistakes to avoid when building drawers?

How do I ensure my drawers are properly aligned?

Can I use pre-made drawer boxes or should I build my own?

What are some advanced techniques for customizing my drawers?

Affiliate Disclosure

Some of the links in this article are affiliate links. If you click through and make a purchase, I may earn a small commission — at no additional cost to you.

This helps support my work so I can continue creating helpful woodworking tutorials and product reviews.I only recommend products and services that I have thoroughly researched and believe could provide real value to my readers.

Thank you for your support!